When a new methodology comes into the survey society, people usually say it’s fantastic but always have reasons to doubt whether it’s trustworthy enough to supplement or even replace the existing way in actual jobs. As a matter of fact, LiDAR has revolutionized the surveying and mapping in the past few decades. Thanks to those interested parties hungering for the latest mapping solution to improve the efficiency because sometimes fieldwork is really a big challenge. Their intellectual curiosity and sound vision do push the industry advancement. This article focuses on some frequently asked questions from the end users who intend to purchase a LiDAR system, and most of the answers might be found in the following story that features a complete user training in the actual survey job.

What if we could not handle the fieldwork operation and data processing even after product training?

This story is about a loyal distributor planning to start LiDAR business as they see the bright market prospects. Like many other potential LiDAR buyers, the decision maker would be more concerned about whether this investment could be productive as desired. If not, the capital for this LiDAR system, usually not small indeed, might go in vain as the staff team are not able to make full use of this costly procurement. Some people say the several-day product training upon delivery will definitely enable the buyers to get started. “It’s true but almost everything is done with the guidance of trainers from the supplier. What if we could not handle the fieldwork operation and data processing even after the well-organized training?” asked Mr. Karnadi Margaka, the smart Indonesia distributor boss. In fact, such anxiety is logical and reasonable because the typical training contents would cover not more than the LiDAR fundamentals and a complete workflow of operational practices. Such a training program seems to be quite fruitful but the beginners will feel it difficult to understand all know-hows in the early stage. “LiDAR is a solution other than simply an independent product, the survey execution of which demands a series of overall considerations and job plans.” according to Ms. Jane Jia, a Z-Lab LiDAR product engineer as well as one of the trainers. “Since the outcomes from laser point cloud vary in how to implement the LiDAR survey, the site knowledge and field-to-office experience would be very crucial, which enables the users to adjust themselves to various circumstances.” she explained.

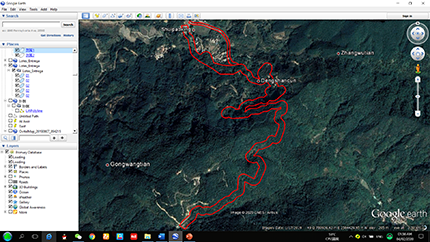

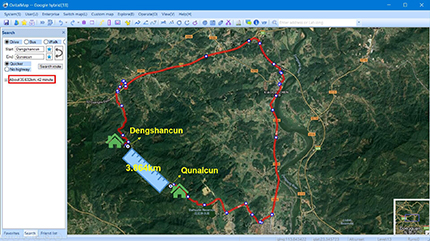

Instead of the regular product guidelines, a project-based training program was delivered to the distributor team intended to learn from A to Z. In other words, the manufacturer trained the distributor team in one of their actual projects with specific requirements and deadline. The job was about 1:500 topography targeted to rural roadway engineering and the survey zone appeared like a narrow corridor (see Fig. 1) with a coverage of 23 hectares. The mission area came from the middle part of 2 neighboring villages without shortcuts in between. Despite 4 kilometers away from each other in linear distance, the villagers had to take a long ride, at least one hour or even more than that, with a very big U-turn (see Fig. 2) during any joint event. Consequently, the local government decided to develop a straight way for mutual benefit in the long run, just like what many other communities did to boost shared prosperity and regional communication.

(Fig. 1, the mission zone shown in GoogleEarth) (Fig. 2, the big U-turn to ride for the villagers)

How to build up a specialized team consisting of experienced UAV pilots and capable processing staff?

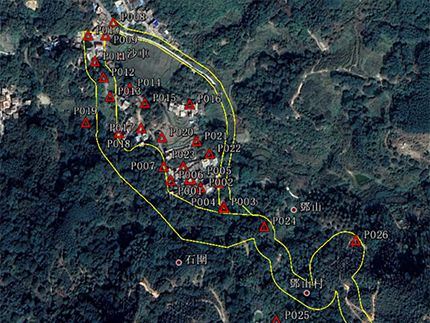

Located in Zengcheng District, Guangzhou, the survey zone was just around 70-minute driving from the office. The discoveries during site visit was quite similar to what the team noticed from terrain analysis in GoogleEarth before leaving for the destination. Keeping an almost 90% vegetational cover (see Fig. 3), the target area, though not big indeed, features typical hilly terrain with an approximate 100-meter vertical height drop, which would be a tough challenge for conventional ground measurements with total station or GNSS RTK. “Not easy, men! How to obtain RTK fixed solutions under the dense tree canopies and accomplish the sufficient results in such highly undulating hills?” said Engr. Rian Stadyanto, Technical Manager of the distributor company. While looking around the site on foot, the guys found that the accessibility into the forest added another issue, as passing through the woods was not fun at all. Compared with UAV photogrammetry, UAV-based LiDAR survey should be a better solution for elevation accuracy control, as the job employer expected 10 centimeters in vertical deviation. “By penetrating the gaps between tree branches and leaves, the laser scans could reach the bare earth surface. What we need is only the true ground points that represent the true ground surface, right? And we would be well acknowledged of the terrain and environment characteristics when searching suitable spots for UAV take-off.” elaborated Engr. Jerry Xie, the other trainer as well as the project manager of this survey job.

After the site research and some preparations, the team started their task. Hardware system assembly and ground base station setup could be nothing more than a few tips and practices (see Fig. 4), which was quite an easy job for the two quick learners. For the mission, LiDAR SZT-R250 and DJI Matrice 600 were in service. They adjusted the flight parameters a little bit by increasing the AGL (Above Ground Level), as flight safety shall be the top concern against the elevated terrain. When the base recording, drone status, remote control and LiDAR system setting were all ready, the UAV carrying the LiDAR and camera got the command to take off and proceeded with its mission of aerial data acquisition. Jerry talked to his teammates, “The drone flight is just a piece of cake because DJI flight operation and ground control are fairly user friendly. However, the most important part of UAV-based LiDAR survey fieldwork is how to manipulate these tools to obtain quality data in accordance with the job demands and actual environment. Appropriate parameter setting and reasonable flight altitude will always bring us satisfactory results. After all, such skillful operation and successful implementation is the key.” A useful tip as well as a mere platitude, according to all suppliers, is that practice makes perfect, as the proverb goes. Obviously, both direct learnings and borrowed experience could help a great deal, yet the latter option allows the beginners to encounter much fewer roundabouts in practice. “Being with the veterans, I feel more confident because their intuitive instructions and painful lessons would just enrich my knowledge and understanding. And we don’t have to touch the spikes and suffer ourselves after learning about their past bitter taste. It’s really awesome, isn’t it?” The other earnest trainee, Engr. Axel Tobias, narrated.

(Fig. 3, the elevated and vegetated survey area) (Fig. 4, working hard on field practices…)

Could LiDAR output accuracy satisfy the topographic job needs?

In total, 5 aerial missions in 2 days drew to a close for completing the data acquisition against the 5 portions of the entire survey zone, as they had no choice but move between the 3 specified take-off points by long rides and uphill struggles. Then, the 2 trainees came up with another topic and Rian asked, “How to verify the data quality? Many surveyors good at total station or RTK measurements are mightily curious to know the way out, because output accuracy is the priority in survey work, which might be always emphasized by the job employer.” This is what serious rookies mostly think about. Fortunately, the 2 young men were lucky enough to see how the Z-Lab team handled these issues in the actual work. “Generally speaking, the data quality check includes not only accuracy verification, but also some other aspects such as data integrity, point density and point cloud thickness. These 4 elements are the major criteria of raw data quality check. Before handing over the data to processing center, we do need to check the data quality.” Jerry emphasized, “Nobody would like to go back and repeat because sometimes the site is really far away. Moreover, it's a waste of time and shame!” Shortly after the aerial missions, Axel and Rian were instructed to do some RTK measurements by the team (see Fig. 5). Such 27 points (see Fig. 6) were mostly taken on the hard ground surface instead of soft soil or vegetation part. “Why not measure some points in the bush or grass and then compare? The accuracy level control in the vegetation is what all geodetic engineers are intensely eager to see.” Rian expressed his idea again with a perplexed look on the face, and definitely it was another typical question from the insiders.

(Fig. 5, Rian and Axel were measuring RTK checkpoints with Jerry…) (Fig. 6, distribution map of 27 checkpoints)

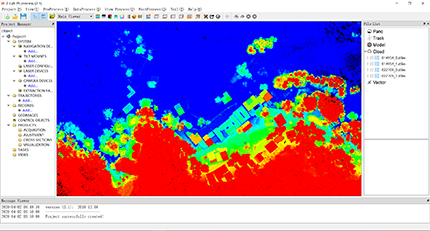

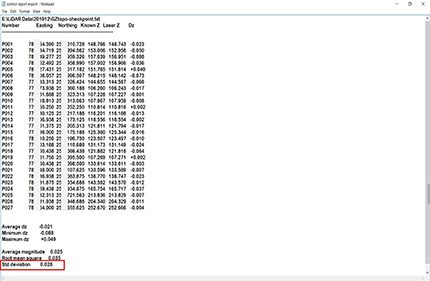

The initiatives of the trainees did please Jane who considers the training communication is indeed a chance and a culture of sharing. She told the 2 young gentlemen, “The points that we measure in the vegetation part might not be exactly the same points that we may obtain in the laser point cloud. In a sense, the deviation comparison is not convincing at all. RTK measurement in the bush or grass is truly a simple act and we may obtain the results, fixed solution or float, as the carbon fiber pole tip reaches the ground physically. This physical act would most probably pass through some vegetational obstructions that might disable the laser scans to reach the ground in reality. Then in the software comparison, the algorithm just picks the nearest point that has been scanned, which is sometimes quite far away from that point we measure in the densely vegetated zone. Do you think this comparison makes sense?” This valuable message was nothing but a beacon of scientific enlightenment in a vast sea of darkness to the 2 diligent guys who smiled to each other while coming to understand the clue. They followed the team and started to process the data step by step. The geo-referenced point cloud (see Fig. 7), generated in software Z-Lab Pt-process, came from the raw laser point data plus the aerial trajectory information consisting of positioning and orientation. After importing the checkpoints to the point cloud in software TerraSolid, the control report presented quite a satisfactory result that the standard deviation, between RTK checkpoints and the corresponding laser dots, was controlled below 3 centimeters on average (see Fig. 8). “When the laser point cloud is accurate enough, the DSM and DEM generated from the point cloud could be reliable too, as the raw data is the fundamental of all upcoming approaches and in particular, DEM is very critical in topography. Am I right?” And this time, Rian received a positive feedback from the trainers with thumbs-up signs.

(Fig. 7, the generated geo-referenced point cloud) (Fig. 8, control report to show standard deviations)

Click http://www.southinstrument.com/video/lists.html?v_id=28&sol_tid=6 for the video story.